| |

| Measuring Spring Stiffness |

Spring and Rubber Band Analysis

A spring (a rubber band is a type of spring), provides a restoring force in proportion to the distance it is extended, i.e. the more one stretches a spring the larger the restoring force. The simplest springs have the following linear relationship:

where,

Fspring => is the force applied by the spring

k => is the spring stiffness

Lrest => Rest length of spring, when no load is applied to it

Linital => Initial length of spring, which is equal to Lrest only for springs with no pretension

Lspring => Length of spring when under load

δx => is the spring elongation; δx=Lspring-Lrest

Compression vs. Tension

Compression springs are designed to experience compressive forces and therefore become shorter when loaded. There are gaps between each turn in the unloaded position to allow them to be compressed (see Figure 1). While compression springs can theoretically be in tension, they are generally not used for that purpose.

Figure 1: Compression Spring

Tension springs are designed to experience tension forces and therefore become longer when loaded. Typically there are no gaps between the turns when they are unloaded (see Figure 2), and many tension springs are manufactured under an initial pretension. This means that the length of the spring will not be displaced unless the magnitude of the tension force is greater than the initial pretension force. Unlike compression springs, tension springs do no have the ability to be used in both compression and tension.

Figure 2: Tension Spring with pretension caused by contact forces between coils

.Measuring Spring Stiffness

An easy way to measure a spring’s stiffness is to hang weights from it and measure the spring elongation. However, there are a few important factors to consider:

-

Verification of Linearity. While it is theoretically possible to measure spring stiffness from just two points, one should always measure at least three points to verify that the spring is behaving in a primary linear fashion.

-

Apply loads on a spring large enough to remove any initial slack or friction.

-

Pretension of spring. If the spring has pretension, like most extension springs, remember that the initial length, Linital, of the spring does not correspond to the rest length of the spring, Lrest.

-

Use an alternate way to calculate stiffness by hanging a mass on the spring and measuring the period of oscillation. Use the equation of free vibration to determine spring stiffness. Only do this for the small spring and small rubber band.

Spring Testing Setup

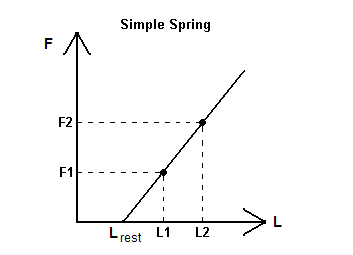

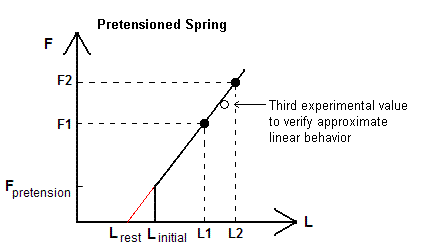

Measure the spring stiffness by applying two loads on the spring and measure spring displacements. As shown below, a spring with pretension will have an Lrest which is different than Linital. The red segment shows the theoretical region of the spring if it was not pretensioned.

|

|

|

|

Spring with no pretension

|

Spring with pretension

|

A minimum of two points is required to calculate a slope. Ideally, more points should be measured and a slope can be calculated using a least squares fit. For the purposes of this worksheet, only two points are needed to obtain an approximate stiffness value. The following formula can be used to calculate the stiffness k.

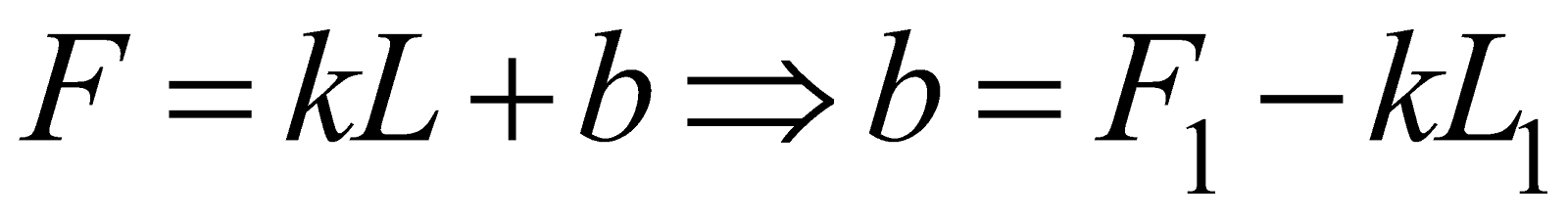

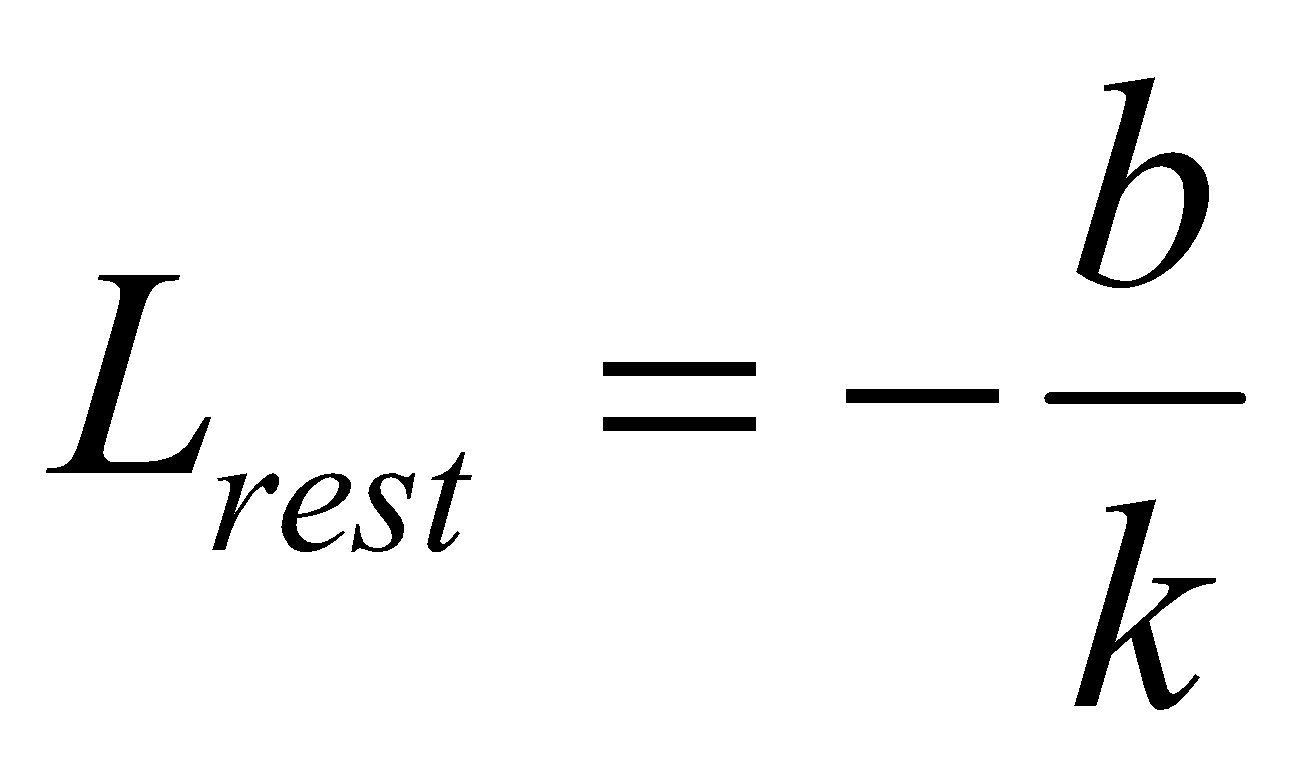

For springs with pretension the rest length must be calculated by first finding the equation of the line that fits the spring curve. The equation of the line can be written as:

.Lrest can then be found by finding the point on the curve where F=0 (by definition of Lrest). Solving for Lrest:

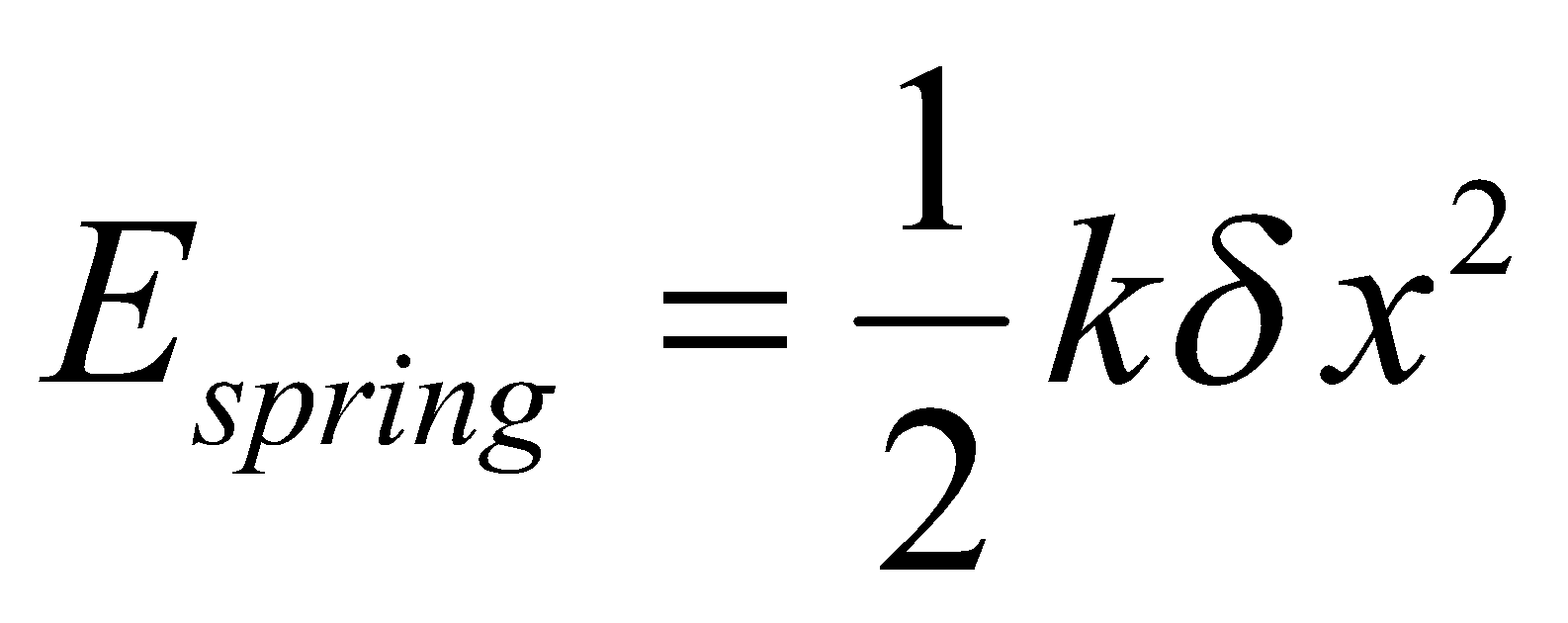

The theoretical equation for the energy stored in a spring is given by:

(for no pretension)

(for no pretension)

For springs with pretension, one cannot recover energy in the regions where the coils touch, and therefore:

Use weights, rulers, and spring scales to fill out the following sheet for each spring and rubber band in the kit:

* Rubber Band Max Length: measure the length (we use different rubber bands each quarter). Do not damage your springs by extending them beyond their elastic limit. See Posted Sheet above the torque measurement devices for the Spring Max Lengths.

Spring Release Time

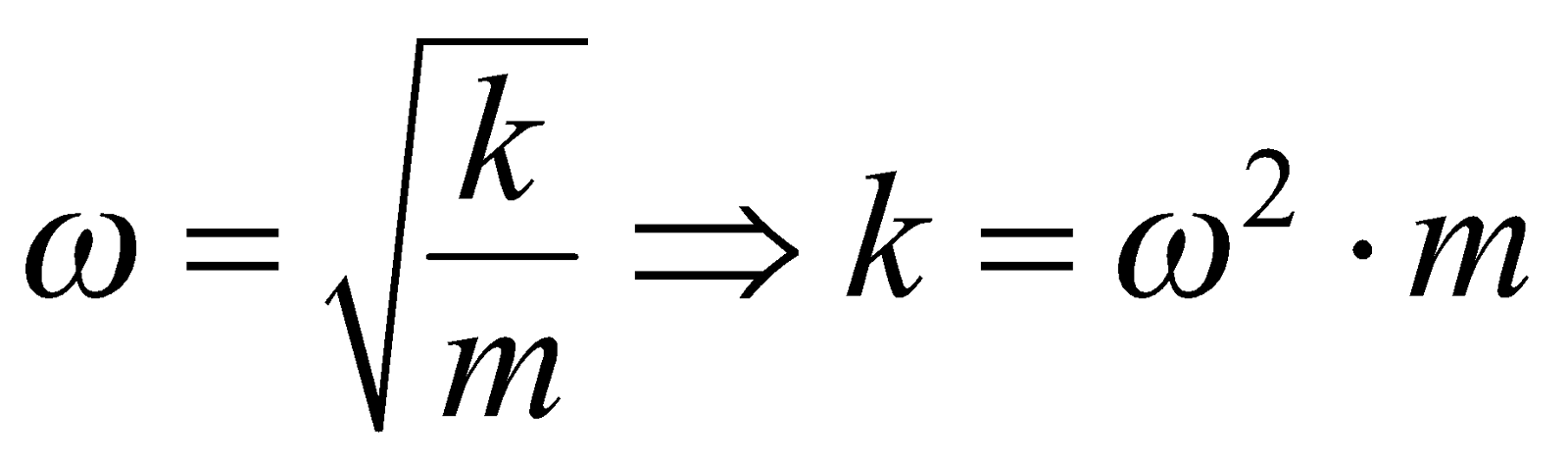

A spring contracts quickly so it can be difficult to measure the release time with a stop watch. Accordingly we attach a mass that the spring will move, and then stretch and release the mass while the spring is hanging. The frequency of vibration, ω, is given by:

(radians/second),

(radians/second),

where macc is the mass that is being accelerated (not the spring mass!) in kg.

The period of one cycle of vibration is given by: T = 2π/ω seconds

However, it takes only one quarter of cycle for the mass to move from a point where the spring is at maximum compression and the mass is at zero velocity (all the energy is in the spring) to the point where the spring is at rest but the mass is at maximum velocity (all the energy is in kinetic energy). Therefore, the energy release time is on equarter of the period. Thus,

trelease = T/4 = π/2ω

.

Experimental Validation

Oftentimes, physical parameters can be measured more than one way. Using multiple methods of finding the same parameter is a useful means for validating the accuracy and validity of a measured value. For springs, the stiffness constant can also be estimated from free oscillation of known mass, where