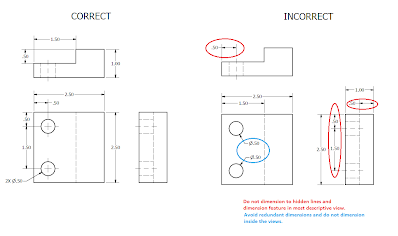

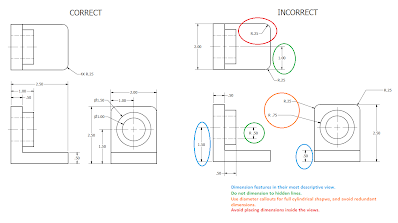

Dimensioning is a critical component of machine design. A dimensioned drawing must be able to show machinist all the information they need to make a part or quote a bid. Good dimensioning is based upon following specifics rules and understanding how parts will be machined. Tolerancing is also very important and it specifies where high precision is required. However, this assignment will cover basic dimensioning, but not tolerancing. The American Society of Mechanical Engineers (ASME) –ANSI/ASME Y 14.5M 1994 standard defines the guidelines for application of dimensions. The reading in the MAE3 course packet covers the basic guidelines which must be followed in this assignment. Students are highly encouraged to learn more about dimensioning and tolerancing on their own. Basic Dimensioning Rules: 1. One must be able to calculate the dimensions of all features. 2. Do not put redundant or dependent dimensions (except as a reference). 3. Dimensions should be placed in orthographic projections and not isometric views. 4. Apply dimensions to a feature in its most descriptive view. 5. Dimension between views. 6. Keep dimensions outside of object lines in the view. 7. Dimensions lines should not cross. Therefore, place smaller dimensions inside of larger dimensions. 8. Holes and Cuts have special format seen in examples below. Capital R specifies radius dimension and Ø specifies a diameter. 9. Dimension to visible object lines, not to hidden lines. 10. Extension lines may cross object lines and other extensions lines when neccasary. 11. Dimension the diameter of cylindrical holes in the view in which the circular profile is seen. 12. Dimension the radius of circular arcs in the view where the curve is shown. 13. Avoid overly long extension and leader lines whenever possible.

Dimensioning Examples (click pictures to see a larger version)

|

CAD Resources >