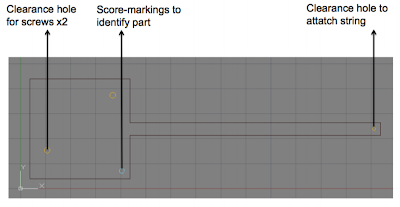

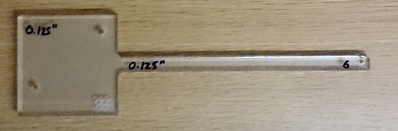

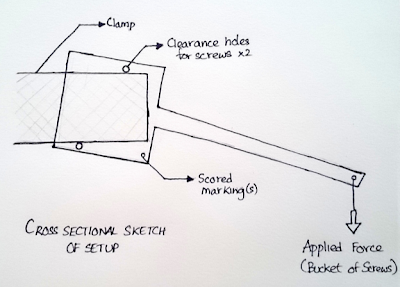

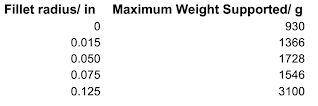

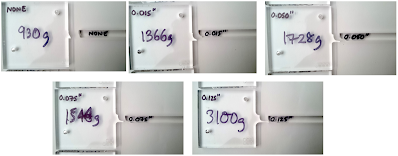

Stress Concentration in Acrylic Cut PartsIn brittle materials sharp corners and other shapes can cause stress concentrations which weaken the parts. Since acrylic is brittle (it cracks when you drop it), it is recommended to put a radius on a corner to prevent a crack from starting there. An MAE3 student, Siddarth Govindan, wanted to know if this was indeed true, and how much would a radius really help. He cut out a number of cantilever beams with varying radiuses, and hung weights on them until they broke. Test Setup A number of test parts resembling cantilever beams were cut out from an acrylic sheet using the Lasercamm. Each part had a different fillet radius ranging from 0.015" to 0.125" and a control part with no fillet radius applied. Two screws were inserted into the holes on the square area of the part and then the part was clamped loosely, ensuring that the fillet was jutting out of the clamp. A second part was also clamped at the other end of the clamp to ensure that uniform pressure was exerted on the parts during the test. An empty bucket attatched to a string was tied to the hole at the end of the part and allowed to hang. For each trial the bucket was slowly filled with screws until the part broke. Then, the weight of the bucket and screws in it were measured using a digital weighing scale or a spring balance as required. Test Results Conclusions and Recommendations From the results and the graph, it is clear that adding a fillet does in fact significantly increase the load that the part can take before snapping. There was approximately a 47% increase in maximum weight supported from a no fillet to a 0.015” fillet part. There was approximately a 127% increase in maximum weight supported from a 0.015” fillet to a 0.125” fillet part. This suggests that adding a fillet with a larger radius should, in general allow the part to support more weight. However, even adding a small fillet radius is significantly better than no fillet. Thus, it is desirable to use a small fillet (thereby minimally affecting aesthetics) rather than not use one at all. Note: For a more precise account and a discussion on the evolution of the test parts, please see the attatched pdf at the bottom of the page. |

|

|